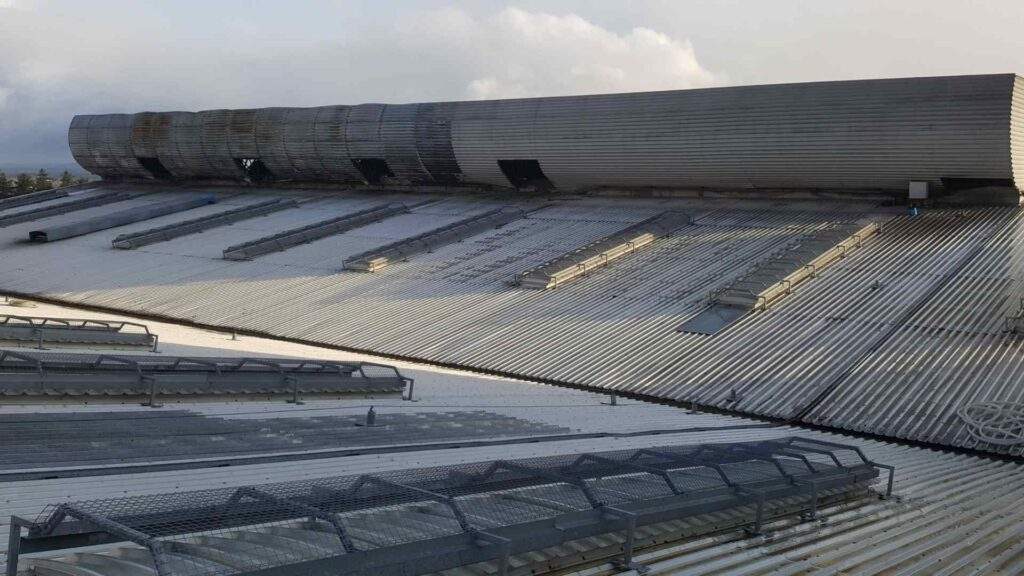

Our Corby Steel fabrications team were involved in the planning, project management, professional rigging, steel fabrication, cladding and replacement of roof filtration units from start to finish. The team leader reported directly to the Encirc production site management.

Phase 1 of the project involved the careful separation of the roof boathouse into 4 sections (Each section weighing 6.25T). Each section of the boathouse was carefully lifted by a 500 tonne crane at a distance of 80m and set down to an area for repairs to commence. The roof filtration system was made up of 30 individual units, each weighing 250kg, and was lifted from the same 80m distance to allow for the installation of a new filtration system.

Phase 2 of the project was the inspection, repair and replacement of structural steel and cladding. This phase was carried out while the boathouse was at ground level. This allowed greater access to the work area with the use of MEWPS.

Phase 3 saw the installation of the new filtration units put into position, which allowed for the re-instating of the 4no. repaired and clad boathouse sections. The sections were structurally joined and clad on the roof which completed the project

Our Corby Steel fabrications team were involved in the planning, project management, professional rigging, steel fabrication, cladding and replacement of roof filtration units from start to finish. The team leader reported directly to the Encirc production site management.

“Kish Fish now have a brand that gives us the confidence to develop our retail skills. We’re thrilled with the outcome and feel reinvigorated with our new look. Customers are impressed too!”

Bill O’Meara, CEO, Kish Fish

MACHINE INSTALLATION & RELOCATION

Our movers’ team were involved in the planning, project management, professional rigging, skating and positioning of a new fin folding production line for a valued client. The machinery was delivered from the manufacturing facility in Turkey to the client’s production site in 3 consignments.